The Power of Aluminum Exploring the Benefits of Aluminum Power Cables

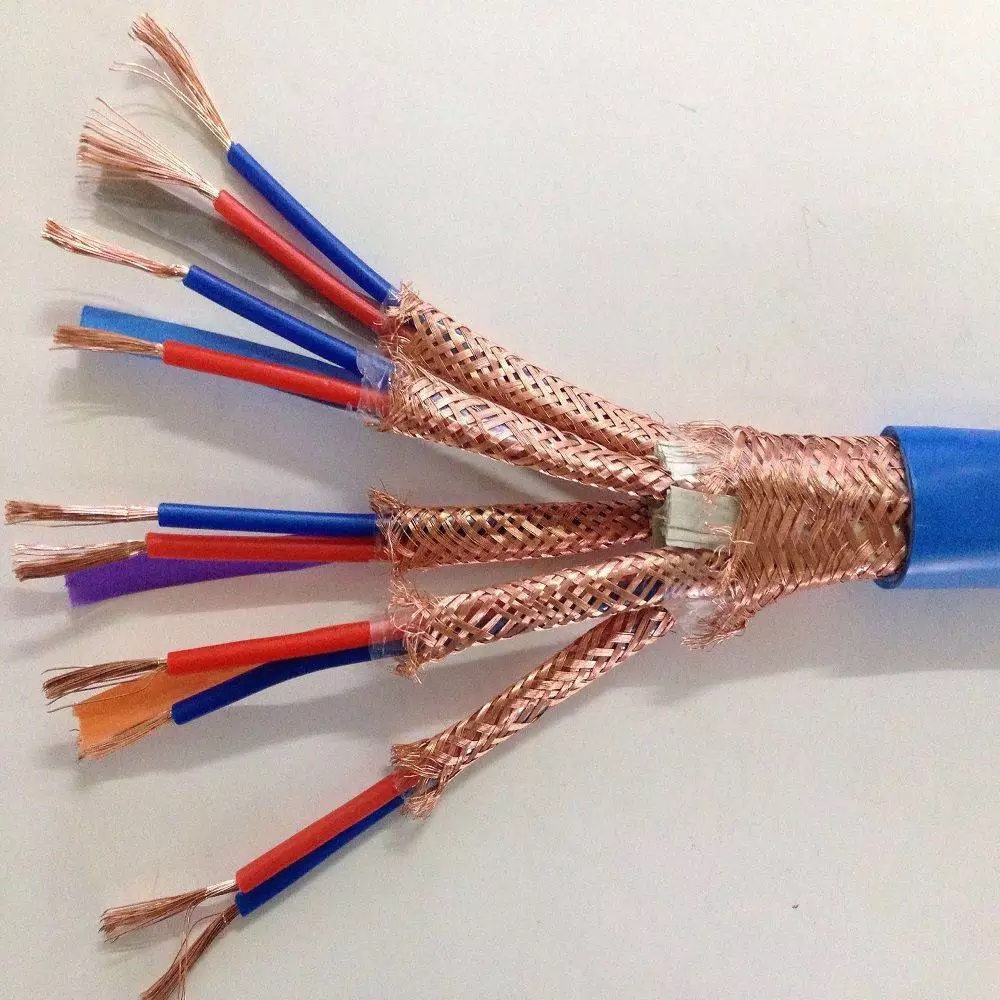

Introduction In the realm of power transmission and distribution, the choice of materials for cables plays a crucial role in ensuring efficiency, reliability, and cost-effectiveness. Among the various materials used for power cables, aluminum has emerged as a popular option due to its unique properties and advantages. In this comprehensive article, we will delve into the world of aluminum power cables, examining their composition, characteristics, applications, benefits, and considerations for installation and maintenance. Composition and Structure of Aluminum Power Cables Aluminum power cables are primarily composed of high-purity aluminum conductors that are designed to carry electrical current from one point to another. The conductors are usually stranded to enhance flexibility and reduce the risk of breakage. The strands are typically made of multiple aluminum wires twisted together to form a single conductor, which is then insulated with various materials to protect against electrical faults and environmental factors. The insulation materials used in aluminum power cables can vary depending on the specific application and environmental conditions. Common insulation materials include polyethylene (PE), cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), and polyvinyl chloride (PVC). These materials provide electrical insulation, mechanical protection, and resistance to moisture, heat, and chemical exposure. In addition to the conductor and insulation, aluminum power cables may also include protective layers such as metallic shields, armors, and jackets to enhance their durability and performance in demanding environments. These additional layers serve to protect the cable from external mechanical stresses, electromagnetic interference, and environmental hazards. Characteristics of Aluminum Power Cables Aluminum power cables exhibit several key characteristics that make them suitable for a wide range of applications in power transmission and distribution systems. High-temperature mineral cables of the notable characteristics of aluminum power cables include: 1. Lightweight: Aluminum is significantly lighter than copper, making aluminum power cables easier to handle and install, especially in large-scale projects where weight savings can translate to lower installation costs and reduced labor requirements. 2. High Conductivity: Despite being less conductive than copper, aluminum still offers good electrical conductivity, allowing for efficient transmission of electrical power over long distances without significant power losses. 3. Corrosion Resistance: Aluminum is naturally resistant to corrosion, which makes aluminum power cables well-suited for outdoor and underground installations where exposure to moisture and corrosive substances is a concern. 4. Cost-Effective: Aluminum is more abundant and less expensive than copper, making aluminum power cables a cost-effective solution for power transmission projects that require long cable runs or high voltage applications. 5. Thermal Stability: Aluminum power cables exhibit good thermal stability, allowing them to withstand high operating temperatures without degradation in performance or insulation integrity. Applications of Aluminum Power Cables Aluminum power cables find widespread applications in various sectors and industries where reliable and efficient power transmission is essential. Some of the common applications of aluminum power cables include: 1. Overhead Power Lines: Aluminum conductors are commonly used in overhead power lines to transmit electricity over long distances. The lightweight and corrosion-resistant nature of aluminum make it an ideal choice for overhead installations where durability and cost-effectiveness are key considerations. 2. Underground Power Distribution: Aluminum power cables are also used in underground power distribution systems to deliver electricity to residential, commercial, and industrial facilities. The corrosion resistance of aluminum helps to protect the cables from moisture and environmental factors in underground installations. 3. Industrial Applications: Aluminum power cables are widely employed in industrial settings such as manufacturing plants, refineries, and mining operations where heavy-duty power transmission is required. The high conductivity and thermal stability of aluminum make it a reliable choice for industrial applications that demand consistent power supply. 4. Renewable Energy Projects: Aluminum power cables play a crucial role in renewable energy projects such as solar farms, wind farms, and hydroelectric plants where large-scale power generation and distribution are essential. The lightweight and cost-effective nature of aluminum cables make them well-suited for renewable energy installations. Benefits of Aluminum Power Cables The use of aluminum power cables offers a multitude of benefits to power utilities, electrical contractors, and end-users alike. Some of the key benefits of aluminum power cables include: 1. Cost-Effectiveness: Aluminum is a more affordable material compared to copper, making aluminum power cables a cost-effective option for power transmission projects that require long cable runs or high voltage applications. The lower material cost of aluminum cables can lead to significant cost savings in large-scale installations. 2. Lightweight: The lightweight nature of aluminum power cables makes them easier to handle and install, reducing labor requirements and installation time. This is particularly advantageous in projects that involve long cable runs or overhead installations where weight savings are crucial. 3. High Conductivity: Although not as conductive as copper, aluminum still offers good electrical conductivity, allowing for efficient transmission of electrical power over long distances. Aluminum power cables can effectively carry high voltage currents without significant power losses, ensuring reliable power delivery. 4. Corrosion Resistance: Aluminum power cables are naturally resistant to corrosion, making them suitable for outdoor and underground installations where exposure to moisture and environmental elements is a concern. The corrosion resistance of aluminum cables helps to maintain their performance and longevity in harsh environments. 5. Durability: Aluminum power cables are known for their durability and long service life, making them a reliable choice for power transmission applications that require dependable performance over an extended period. The robust construction and high-quality materials used in aluminum cables contribute to their longevity and reliability. Considerations for Installation and Maintenance While aluminum power cables offer numerous benefits, there are certain considerations that should be taken into account during installation and maintenance to ensure optimal performance and longevity. Some key considerations include: 1. Proper Sizing: It is essential to correctly size aluminum power cables based on the expected load and voltage requirements to prevent overheating and power losses. Undersized cables can lead to excessive heat generation and voltage drop, while oversized cables can result in unnecessary material costs and installation complexities. 2. Termination and Splicing: Proper termination and splicing of aluminum power cables are critical to ensure reliable electrical connections and prevent issues such as overheating, arcing, and insulation breakdown. It is important to follow manufacturer recommendations and industry best practices when terminating and splicing aluminum cables. 3. Environmental Factors: Aluminum power cables should be installed in accordance with relevant codes and standards to protect against environmental factors such as moisture, heat, cold, and chemical exposure. Proper cable routing, protection, and insulation are essential to safeguard the cables from damage and ensure long-term performance. 4. Maintenance Practices: Regular inspection and maintenance of aluminum power cables are essential to detect any signs of wear, damage, or degradation that could compromise their performance. Periodic testing, cleaning, and thermal imaging can help identify potential issues early and prevent costly downtime or failures.  Conclusion Aluminum power cables have become a popular choice for power transmission and distribution applications due to their cost-effectiveness, lightweight nature, high conductivity, corrosion resistance, and durability. By understanding the composition, characteristics, applications, benefits, and considerations for installation and maintenance of aluminum power cables, stakeholders in the electrical industry can make informed decisions when selecting and deploying these cables in various projects. With proper installation and maintenance practices, aluminum power cables can provide reliable and efficient power transmission solutions for a wide range of applications, contributing to the advancement of modern power systems.

Conclusion Aluminum power cables have become a popular choice for power transmission and distribution applications due to their cost-effectiveness, lightweight nature, high conductivity, corrosion resistance, and durability. By understanding the composition, characteristics, applications, benefits, and considerations for installation and maintenance of aluminum power cables, stakeholders in the electrical industry can make informed decisions when selecting and deploying these cables in various projects. With proper installation and maintenance practices, aluminum power cables can provide reliable and efficient power transmission solutions for a wide range of applications, contributing to the advancement of modern power systems.